Product Categories

- Home

- Product Categories

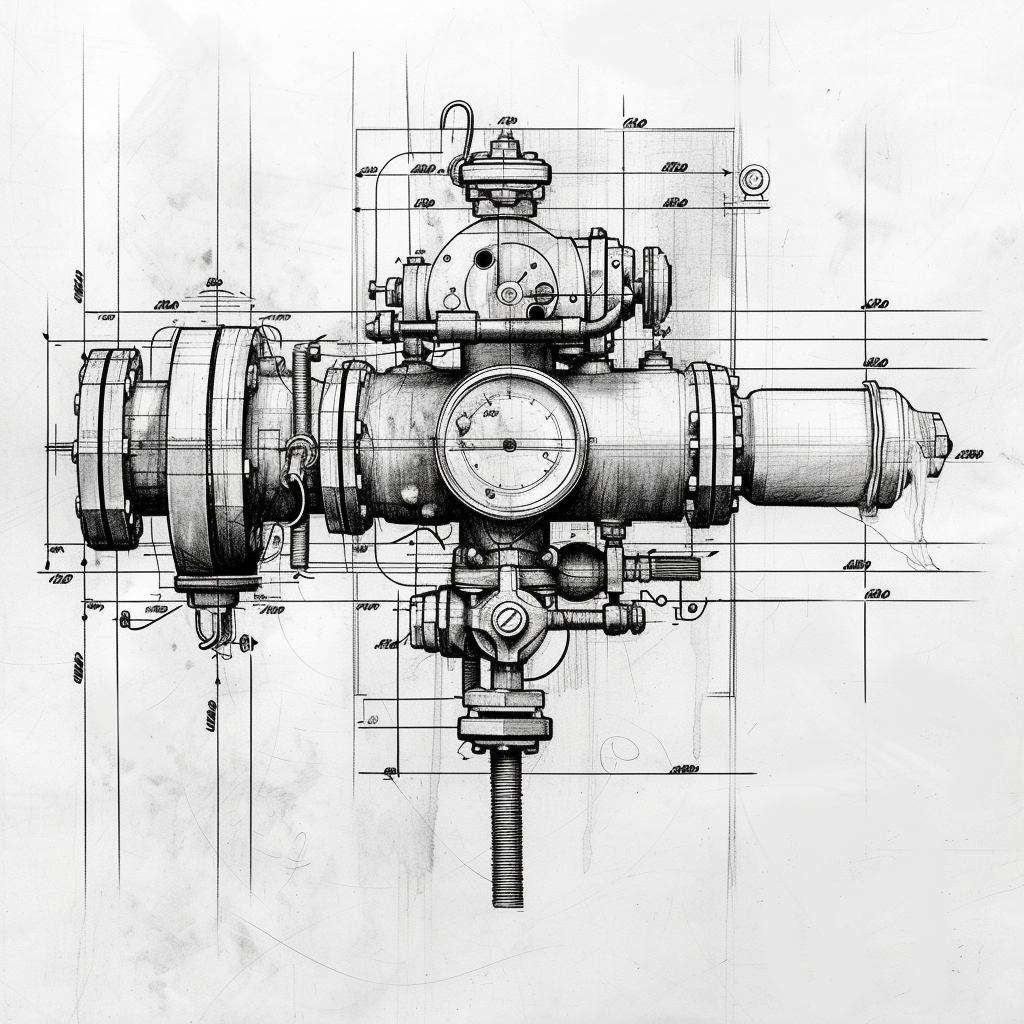

INDUSTRIAL VALVES

Flow Control Valves: Managing Water, Steam, and Oil Flow

Globe Valves:

- Suitable for a wide range of applications, including water, steam, and oil.

- Design: Globe valves have a spherical body with a plug (disc) that can be moved up and down to control flow through a constricted passageway.

- Operation: They provide good throttling and fine control of flow by varying the position of the plug. They are primarily used for on/off and throttling applications.

Ball Valves:

- Suitable for water and oil applications, but less common for steam due to temperature considerations.

- Design: Ball valves have a spherical closure element (ball) with a hole through it that can be rotated to control flow.

- Operation: Ball valves offer quick, full-bore shut-off or on/off control. They are less suitable for precise throttling compared to globe valves.

Butterfly Valves:

- Suitable for water and some oil applications but not typically used for high-temperature steam.

- Design: Butterfly valves have a flat, circular disc mounted on a shaft that can be rotated to control flow.

- Operation: They are excellent for high-flow, low-pressure drop applications but may not provide precise throttling control. They are often used in HVAC and water distribution systems.

Gate Valves:

- Suitable for water and oil applications but not commonly used for steam due to potential steam trap issues.

- Design: Gate valves have a flat gate-like disc that moves perpendicular to the flow direction to open or close the valve.

- Operation: Gate valves are typically used for on/off control and provide low pressure drop when fully open. They are not ideal for throttling due to their design.

Control Valves (e.g., Globe Control Valves):

- Specifically designed for precise flow control in various applications, including water, steam, and oil.

- Design: These valves resemble globe valves but are equipped with an actuator (electric, pneumatic, or hydraulic) to modulate the valve position based on control signals.

- Operation: Control valves are used for precise and continuous throttling control, making them suitable for applications where flow rates must be adjusted dynamically to meet specific process requirements.

In summary, the choice of flow control valve depends on factors such as the fluid type, temperature, pressure, and the required level of control. Globe and control valves are commonly used for precise control in water, steam, and oil systems, while ball and butterfly valves are suitable for on/off or less precise control. Gate valves are often used for isolation purposes. The design and operation of each valve type are tailored to its intended application.

Sizing flow control valves correctly is crucial to ensure optimal performance and efficiency in a water, steam, or oil flow system. The sizing process involves determining the valve's specifications to meet the system's flow rate, pressure drop, and other requirements. Here are the key factors to consider in the sizing process:

Flow Rate: Determine the required flow rate for your application. This could be based on the desired capacity of the system or the specific process requirements. Flow rate is typically expressed in gallons per minute (GPM), cubic meters per hour (m³/h), or other relevant units.

Pressure Drop: Calculate the allowable pressure drop across the valve. This is the difference in pressure between the inlet and outlet of the valve and is critical for maintaining system performance. Different applications may have varying acceptable pressure drop limits.

Fluid Properties: Understand the properties of the fluid being controlled, including its density, viscosity, and temperature. These properties affect the valve's performance and must be considered in the sizing calculations.

Valve Type: Select the appropriate valve type (e.g., globe valve, ball valve, control valve) based on the specific requirements of the application. Different valve types have different flow characteristics and pressure drop behaviors.

Valve Cv or Kv Value: Every valve has a flow coefficient (Cv or Kv) that represents its ability to pass flow. Calculate or select a valve with the Cv or Kv value that matches the required flow rate. This value is often provided by valve manufacturers and can be used to compare different valves.

Reynolds Number: Calculate the Reynolds number for the fluid flow to determine whether it is in the laminar or turbulent flow regime. This helps in selecting the appropriate valve type and size, as the flow regime affects valve performance.

Valve Authority: Consider the concept of "valve authority," which relates to the ratio of the valve's Cv or Kv to the system's Cv or Kv. A higher valve authority indicates better control and efficiency. Properly sized control valves often have a valve authority of around 0.7 to 0.8.

Safety Margins: Include safety margins in your calculations to account for variations in operating conditions, fluctuations in flow rates, and future system expansions. These margins help prevent undersizing and ensure reliable performance.

Valve Trim: Depending on the valve type, choose the appropriate valve trim (e.g., plug, ball, disk) that suits the desired flow characteristics, such as linear or equal percentage.

Environmental Conditions: Consider environmental factors like temperature, humidity, and potential corrosion or erosion of valve components, especially when dealing with steam or oil applications.

Noise and Cavitation: Ensure that the selected valve size and design minimize noise and cavitation issues, which can impact both valve performance and system integrity.

Local Regulations and Standards: Comply with local regulations and industry standards that may dictate specific sizing criteria and requirements for safety and efficiency.

Consult with Experts: If in doubt, consult with experienced engineers or valve experts who can help with the sizing process and ensure that the selected valve meets all system requirements.

Sizing flow control valves accurately is a complex task that requires a thorough understanding of the system and the characteristics of the fluid being handled. It is essential to follow best practices and guidelines to achieve optimal performance and efficiency while maintaining system safety and reliability.

Selecting the appropriate materials for flow control valves in water, steam, and oil applications is essential to ensure long-term durability and resistance to corrosion or erosion. The critical factors to consider when choosing materials for these applications include:

Fluid Compatibility:

- Identify the specific fluid(s) the valve will handle. Different fluids have varying levels of corrosiveness and erosiveness. Ensure that the selected materials are compatible with the chemical composition of the fluid to prevent corrosion or chemical reactions.

Temperature and Pressure:

- Consider the temperature and pressure conditions under which the valve will operate. High temperatures and pressures can affect material properties and require materials capable of withstanding these conditions.

Corrosion Resistance:

- Evaluate the susceptibility of materials to corrosion by the fluid. Common corrosion-resistant materials include stainless steels (e.g., 316 stainless steel), corrosion-resistant alloys (e.g., Hastelloy), and specialized coatings.

Erosion Resistance:

- In applications with abrasive or erosive fluids (e.g., slurry in oil sands), select materials that are resistant to erosion. Hardened materials or coatings may be necessary to withstand erosive forces.

Material Strength:

- Ensure that the selected material has the necessary mechanical strength to handle the pressure differentials and loads encountered during operation.

Material Certifications:

- Verify that the materials meet industry and regulatory standards. Materials may need to comply with standards such as ASTM, ASME, NACE, or API, depending on the application.

Valve Component Materials:

- Consider the materials used for various valve components, including the body, trim, seals, and gaskets. These components may require different materials to meet the specific demands of the application.

Compatibility with Gaskets and Seals:

- Check the compatibility of valve materials with gaskets and seals to ensure they are chemically compatible and can maintain a proper seal over time.

Thermal Expansion:

- Take into account the coefficient of thermal expansion of the materials, as mismatched expansion rates between different components can lead to mechanical stress and potential failure.

Cost Considerations:

- Weigh the cost of materials against their performance characteristics. Sometimes, high-performance materials come at a higher cost, but they may be necessary to ensure long-term reliability.

Maintenance and Inspection:

- Consider ease of maintenance and inspection. Some materials may require more frequent inspections or maintenance than others, impacting the overall lifecycle cost of the valve.

Environmental Considerations:

- Assess any environmental factors, such as exposure to seawater, harsh weather conditions, or extreme temperatures, that may influence material selection.

Industry Experience:

- Consult with industry experts and valve manufacturers who have experience with similar applications to gain insights into the most suitable materials for your specific needs.

Future Expansion and Changes:

- Anticipate potential changes in operating conditions, system modifications, or expansion plans when selecting materials to ensure the valve can adapt to future requirements.

It's essential to conduct a thorough materials selection process based on these factors to ensure the longevity and reliability of flow control valves in water, steam, and oil applications. Working with experienced engineers and valve manufacturers can provide valuable guidance in making the best material choices for your specific application.

Temperature and pressure variations can significantly impact the performance and reliability of flow control valves in water, steam, and oil systems. Here's how these variations affect valves and measures to mitigate their effects:

1. Temperature Effects:

a. Material Properties: Extreme temperatures can affect the material properties of valve components, leading to changes in strength, hardness, and dimensional stability. This can result in reduced valve performance or even failure.

b. Thermal Expansion: Temperature variations cause materials to expand or contract. Mismatched thermal expansion rates between valve components can lead to mechanical stress and affect the valve's ability to seal properly.

c. Valve Operation: Extreme temperatures can affect the valve's ability to open and close smoothly, leading to operational issues such as sticking or jamming.

Measures to Mitigate Temperature Effects:

- Select materials that are suitable for the operating temperature range. Materials like stainless steel, high-temperature alloys, and specialized coatings can resist thermal effects.

- Use valve components with compatible thermal expansion rates to reduce the risk of mechanical stress.

- Install insulation or heat tracing systems around valves in extreme temperature environments to maintain more stable operating conditions.

2. Pressure Effects:

a. Cavitation: High-pressure differentials can lead to cavitation, a phenomenon where vapor bubbles form and collapse within the valve. Cavitation can cause erosion of valve components and impact performance.

b. Pressure Drop: Pressure variations in the system can affect the valve's pressure drop characteristics, potentially leading to changes in flow rates and system efficiency.

c. Valve Seal Integrity: Fluctuating pressures can affect the sealing integrity of the valve, leading to leaks and reduced control accuracy.

Measures to Mitigate Pressure Effects:

- Use anti-cavitation trim or control valves designed to handle cavitation-prone conditions to prevent erosion damage.

- Ensure that the valve is correctly sized for the expected pressure differentials to minimize pressure drop variations.

- Employ pressure relief devices or safety valves to protect the valve and system from excessive pressure.

3. Combined Temperature and Pressure Effects:

a. Stress and Fatigue: Fluctuating temperature and pressure conditions can induce stress and fatigue on valve components, potentially leading to cracks or failures over time.

b. Material Compatibility: Extreme temperature and pressure conditions may require specialized materials that can withstand both factors simultaneously.

Measures to Mitigate Combined Effects:

- Regularly inspect and maintain valves to identify signs of stress, fatigue, or material degradation, particularly in high-temperature and high-pressure environments.

- Implement temperature and pressure control measures in the system, such as bypass lines, heat exchangers, and pressure regulators, to reduce extreme conditions in the vicinity of the valve.

- Consider the use of thermal expansion compensators, flexible connectors, or bellows seals to accommodate thermal expansion and pressure fluctuations without imposing excessive stress on the valve.

- When selecting valves, consult with valve manufacturers and engineers experienced in high-temperature and high-pressure applications to ensure proper valve design and material selection.

Properly addressing temperature and pressure variations through material selection, maintenance, and system design is essential to maintain the performance and reliability of flow control valves in water, steam, and oil systems, especially in challenging operating conditions.

Maintenance and servicing of flow control valves in water, steam, and oil flow systems are essential to ensure their continued operation and efficiency over time. Here are some general maintenance requirements and best practices for these valves:

1. Regular Inspection:

- Perform routine visual inspections to check for signs of wear, corrosion, leaks, or damage to valve components, such as the body, trim, seals, and gaskets.

- Look for any abnormal noise or vibrations during valve operation, as these can indicate issues with the valve or system.

2. Lubrication:

- Ensure that valve stems, actuators, and other moving parts are properly lubricated according to the manufacturer's recommendations. Lubrication helps prevent excessive wear and reduces friction.

3. Leak Detection:

- Periodically check for leaks around the valve body and connections. Leaks can lead to energy losses and system inefficiencies.

- Monitor packing gland seals and replace them if they show signs of wear or leakage.

4. Calibration and Testing:

- Calibrate control valves and actuators to ensure accurate and precise control of flow rates. Test the valve's response to control signals to maintain process efficiency.

- Check valve positioners and controllers for proper operation and accuracy.

5. Cleaning:

- Remove any debris, dirt, or deposits that may accumulate on valve components, affecting performance.

- In steam and oil systems, consider the use of strainers or filters to protect the valve from particulate matter.

6. Corrosion Protection:

- Apply corrosion-resistant coatings or materials to valve components, especially in corrosive environments or when handling corrosive fluids.

- Regularly inspect the condition of these protective coatings and reapply as necessary.

7. Seal Replacement:

- Replace valve seals and gaskets as needed, especially in high-temperature or high-pressure applications, to maintain sealing integrity and prevent leaks.

8. Pressure Relief Devices:

- Ensure that pressure relief devices or safety valves are functioning correctly to protect the valve and system from overpressure conditions.

9. Documentation and Records:

- Maintain accurate records of valve maintenance, including inspection dates, repairs, replacements, and any performance issues encountered.

- Document any changes in operating conditions or system modifications that may impact valve performance.

10. Training and Personnel:

- Provide training to personnel responsible for valve maintenance and servicing to ensure they have the knowledge and skills to perform their tasks safely and effectively.

11. Spare Parts Inventory:

- Keep a supply of spare parts for critical valve components readily available to reduce downtime in case of unexpected failures.

12. Periodic Overhaul:

- Plan for periodic valve overhauls or maintenance shutdowns, during which valves can be disassembled, inspected, and restored to their original condition.

13. Valve Health Monitoring:

- Consider implementing valve condition monitoring systems or predictive maintenance techniques to detect early signs of valve degradation and plan maintenance accordingly.

14. Compliance with Standards:

- Ensure that valve maintenance practices comply with industry standards, manufacturer recommendations, and any relevant regulations.

Regular and proactive maintenance, combined with proper documentation and personnel training, can significantly extend the lifespan of flow control valves and ensure their continued operation and efficiency in water, steam, and oil flow systems. It also helps prevent unexpected failures that can result in costly downtime and repairs.

WATER METERS

- Types

- Performance Factors

- Technology

Exploring Water Meter Types: Volumetric, Velocity, and Compound

Water meters, crucial for accurate water measurement, come in three main types: volumetric, velocity, and compound. Volumetric meters, employing rotating or oscillating components, excel in accuracy, ideal for residential and small commercial use. Velocity meters measure flow based on water speed, suitable for larger commercial and industrial applications. Compound meters merge both principles, offering precise measurement across various flow rates. These meters cater to diverse demands, ensuring efficient water management and billing accuracy in residential, commercial, and industrial sectors.

Performance factors crucial for water meters include accuracy, reliability, and maintenance. Accuracy ensures precise measurement, vital for billing and resource management. Reliability ensures consistent operation over time, minimizing downtime and ensuring continuous data collection. Maintenance is key for sustained performance, requiring regular checks for sediment buildup, seal integrity, and calibration. Proper maintenance enhances meter longevity, reducing the risk of inaccuracies or failures. Together, accuracy, reliability, and maintenance uphold the integrity of water metering systems, facilitating efficient water management and conservation efforts.

Advancements in water metering technology encompass smart meters, ultrasonic technology, and remote monitoring systems. Smart meters leverage digital communication to provide real-time data on water consumption, enabling proactive management and billing accuracy. Ultrasonic meters employ sound waves to measure flow, offering high accuracy and minimal maintenance needs. Remote monitoring systems enable off-site data collection and analysis, enhancing efficiency and enabling timely interventions. Together, these technologies revolutionize water management, offering improved accuracy, reduced maintenance, and enhanced decision-making capabilities for utilities and consumers alike.

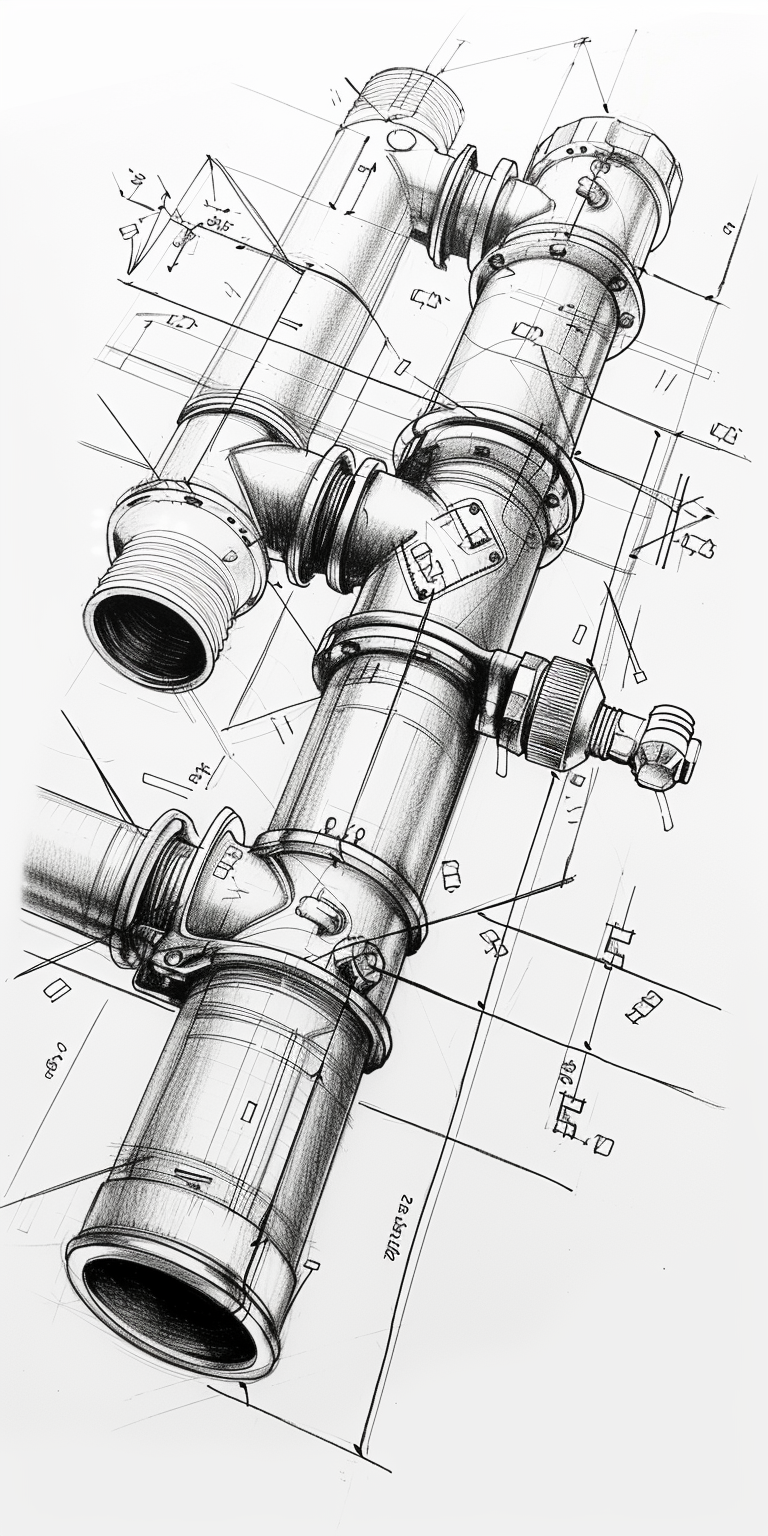

PIPES & FITTINGS

Pipe and Pipe Fittings Overview: CPVC, UPVC, SWR, PVC, and Composite Solutions

CPVC (Chlorinated Polyvinyl Chloride) pipes are suitable for hot water applications due to their high temperature resistance and chemical durability. UPVC (Unplasticized Polyvinyl Chloride) pipes are rigid and corrosion-resistant, commonly used in cold water supply and drainage systems. SWR (Soil, Waste, and Rainwater) pipes are specifically designed for soil and waste drainage, featuring high strength and chemical resistance. PVC (Polyvinyl Chloride) pipes are versatile, used in various applications including water supply, drainage, and irrigation. Composite pipes combine different materials for enhanced strength, durability, and corrosion resistance, suitable for demanding industrial and infrastructure applications. Each type has unique material properties and application suitability, offering a range of solutions for different piping needs.

CPVC, UPVC, SWR, PVC, and composite pipe fittings play vital roles in ensuring the overall integrity and functionality of plumbing and industrial piping systems:

1. Connection: Pipe fittings provide the means to connect pipes together, facilitating the creation of complex piping networks that can transport fluids efficiently.

2. Leak Prevention: Properly installed fittings create secure joints between pipes, minimizing the risk of leaks or bursts that could lead to water damage or system failure.

3. Directional Control: Fittings enable changes in the direction of flow within a piping system, allowing fluids to be directed precisely where needed, optimizing system performance.

4. Adaptability: Pipe fittings come in a variety of shapes and configurations, allowing for adaptation to different pipe sizes, shapes, and materials, enhancing system versatility.

5. Maintenance: Fittings facilitate easy access to pipes for maintenance or repair purposes, enabling quick and efficient servicing of the piping system.

6. Pressure Regulation: Certain fittings, such as valves and regulators, help regulate fluid pressure within the system, ensuring optimal operation and preventing damage from excessive pressure.

7. Corrosion Resistance: Fittings made from corrosion-resistant materials, such as CPVC, UPVC, and composite materials, contribute to the longevity and reliability of the piping system, particularly in corrosive environments.

8. Temperature Resistance: CPVC and composite fittings are specifically designed to withstand high temperatures, making them suitable for hot water and industrial applications where temperature extremes are common.

Overall, CPVC, UPVC, SWR, PVC, and composite pipe fittings are essential components that contribute to the structural integrity, efficiency, and functionality of plumbing and industrial piping systems, ensuring smooth operation and reliable performance.

Several factors should be considered when selecting between CPVC, UPVC, SWR, PVC, and composite pipes and fittings for specific applications:

1. Material Properties:

- CPVC: High-temperature resistance and chemical durability, suitable for hot water supply lines and industrial applications.

- UPVC: Rigid and corrosion-resistant, ideal for cold water supply lines and drainage systems.

- SWR: Designed for soil, waste, and rainwater drainage, featuring high strength and chemical resistance.

- PVC: Versatile and cost-effective, used in various applications including water supply, drainage, and irrigation.

- Composite: Enhanced strength, durability, and corrosion resistance, suitable for demanding industrial and infrastructure applications.

2. Application Requirements:

- Residential Plumbing: Consider factors such as temperature, pressure, and chemical exposure to ensure the selected material can withstand typical residential plumbing conditions.

- Agricultural Irrigation: Focus on factors like UV resistance, abrasion resistance, and compatibility with fertilizers and pesticides commonly used in agricultural settings.

- Chemical Processing: Prioritize chemical resistance, temperature tolerance, and compatibility with specific chemicals or solvents present in the processing environment.

3. Environmental Conditions:

- Exposure to sunlight, temperature extremes, moisture levels, and soil conditions can impact the performance and longevity of pipes and fittings. Select materials that can withstand these environmental factors.

4. System Design and Configuration:

- Consider the layout, size, and complexity of the piping system, as well as the required flow rates and pressure ratings. Choose pipes and fittings that can accommodate the system design and meet performance requirements.

5. Regulatory Compliance:

- Ensure that the selected pipes and fittings comply with relevant industry standards, building codes, and regulations applicable to the intended application, such as NSF, ASTM, or AS/NZS standards.

6. Lifecycle Cost:

- Evaluate the upfront costs, maintenance requirements, and expected lifespan of different pipe and fitting materials to determine the most cost-effective solution over the long term.

By carefully considering these factors, stakeholders can make informed decisions when selecting between CPVC, UPVC, SWR, PVC, and composite pipes and fittings for specific applications, ensuring optimal performance, longevity, and compliance with regulatory requirements.

The installation methods and requirements for CPVC (Chlorinated Polyvinyl Chloride), UPVC (Unplasticized Polyvinyl Chloride), SWR (Soil, Waste, and Rainwater), PVC (Polyvinyl Chloride), and composite pipes and fittings can vary based on their material properties, intended use, and specific standards/regulations in your region. Here's a general overview of the installation methods and best practices for each:

1. CPVC (Chlorinated Polyvinyl Chloride):

- CPVC pipes are commonly used for hot and cold water distribution systems due to their heat resistance.

- Installation typically involves solvent cement welding or mechanical joining methods such as threaded fittings.

- Ensure proper cleaning and preparation of pipe ends before solvent welding.

- Follow manufacturer recommendations for solvent cement application and curing times.

- Use appropriate support and hanger systems to prevent sagging and stress on the pipes.

- Avoid exposure to direct sunlight and high temperatures during installation.

2. UPVC (Unplasticized Polyvinyl Chloride):

- UPVC pipes are often used for cold water supply lines, drainage systems, and irrigation.

- Installation methods include solvent cement welding, threading, or mechanical couplings.

- Clean and prepare pipe ends thoroughly before solvent welding.

- Properly support pipes and fittings to prevent sagging and stress.

- Ensure fittings are properly aligned and securely attached.

- Protect pipes from direct sunlight and extreme temperatures during installation.

3. SWR (Soil, Waste, and Rainwater):

- SWR pipes are designed for soil and waste drainage systems in buildings.

- Installation involves solvent cement welding or rubber ring jointing methods.

- Ensure proper slope for drainage pipes to facilitate flow.

- Use appropriate fittings and supports to maintain alignment and prevent leakage.

- Inspect and test joints for leaks before covering with soil or concrete.

- Follow local building codes and regulations for SWR system installation.

4. PVC (Polyvinyl Chloride):

- PVC pipes are versatile and used in various applications including water supply, drainage, and irrigation.

- Installation methods include solvent cement welding, threading, or mechanical couplings.

- Clean and dry pipe ends before solvent welding.

- Properly support pipes to prevent sagging and stress.

- Avoid excessive bending or over-tightening fittings.

- Protect pipes from direct sunlight and extreme temperatures during installation.

5. Composite Pipes and Fittings:

- Composite pipes are typically made from a combination of materials such as PVC, aluminum, and/or other polymers.

- Installation methods may vary based on the specific composition and intended use of the composite pipe.

- Follow manufacturer guidelines and recommendations for installation procedures.

- Ensure compatibility of fittings and joints with the composite pipe material.

- Properly support and secure composite pipes to prevent damage and leakage.

- Inspect and test joints for leaks before covering or concealing.

General Best Practices for All Types of Pipes and Fittings:

- Adhere to relevant building codes, standards, and regulations.

- Use high-quality materials from reputable manufacturers.

- Ensure proper sizing and compatibility of pipes and fittings.

- Perform pressure testing and inspections before concealing installations.

- Provide adequate expansion joints and allowance for thermal expansion.

- Protect pipes from physical damage, chemical exposure, and excessive loads.

- Train installers on proper techniques and procedures for installation.

- Regular maintenance and inspection to detect and address any issues promptly.

Always consult with local authorities and professionals familiar with local regulations and best practices for specific installation requirements in your area.

Each type of pipe and fitting solution has its own set of advantages and limitations. Optimizing the selection and usage of piping systems involves considering these factors in conjunction with specific project requirements to achieve cost-effectiveness and reliability. Here's a breakdown of the main advantages and limitations of each type, along with optimization strategies:

1. CPVC (Chlorinated Polyvinyl Chloride):

- Advantages:

- High heat resistance, suitable for hot water applications.

- Corrosion-resistant and durable.

- Lightweight and easy to install.

- Good chemical resistance.

- Limitations:

- Limited temperature and pressure ratings compared to metal pipes.

- Susceptible to degradation over time with exposure to certain chemicals.

- Optimization:

- Select appropriate CPVC schedule and sizing based on temperature and pressure requirements.

- Use CPVC in applications where its temperature and chemical resistance properties offer significant advantages.

- Follow manufacturer guidelines for installation and maintenance to maximize longevity.

2. UPVC (Unplasticized Polyvinyl Chloride):

- Advantages:

- Excellent chemical resistance.

- Lightweight and easy to install.

- Smooth interior surface, reducing friction loss.

- Cost-effective compared to some other materials.

- Limitations:

- Not suitable for high-temperature applications.

- Can become brittle over time, especially in cold environments.

- Optimization:

- Use UPVC for cold water supply lines, drainage systems, and irrigation where its properties are well-suited.

- Avoid exposure to extreme temperatures to minimize brittleness.

- Properly support and protect UPVC pipes from physical damage.

3. SWR (Soil, Waste, and Rainwater):

- Advantages:

- Designed specifically for drainage systems, providing efficient waste removal.

- Chemical and corrosion-resistant.

- Long service life with minimal maintenance.

- Limitations:

- Limited to specific applications within buildings.

- Requires proper slope for effective drainage.

- Optimization:

- Select appropriate SWR pipe size and slope according to building codes and drainage requirements.

- Ensure proper installation and sealing of joints to prevent leaks.

- Regular inspection and maintenance to keep drainage systems functioning optimally.

4. PVC (Polyvinyl Chloride):

- Advantages:

- Versatile and widely used in various applications.

- Corrosion-resistant and durable.

- Lightweight and easy to install.

- Cost-effective compared to many other materials.

- Limitations:

- Not suitable for high-temperature applications.

- May become brittle over time, especially in cold environments.

- Optimization:

- Utilize PVC in applications where its properties meet requirements, such as water supply, drainage, and irrigation.

- Protect PVC pipes from direct sunlight and extreme temperatures to extend their lifespan.

- Properly support and secure PVC pipes to prevent damage.

5. Composite Pipes and Fittings:

- Advantages:

- Combine properties of different materials for enhanced performance.

- Can offer improved strength, flexibility, or corrosion resistance compared to single-material pipes.

- Versatile and adaptable to various applications.

- Limitations:

- Higher cost compared to some single-material pipes.

- Compatibility issues between different materials in composite pipes.

- Optimization:

- Evaluate specific project requirements to determine if composite pipes offer advantages over single-material options.

- Select composite pipes with materials that provide the desired combination of properties for the application.

- Follow manufacturer guidelines for installation and maintenance to ensure optimal performance.

Overall Optimization Strategies:

- Conduct a thorough evaluation of project requirements, including temperature, pressure, chemical exposure, and budget considerations.

- Consider lifecycle costs, including installation, maintenance, and potential replacement.

- Consult with industry experts and manufacturers to select the most suitable pipe and fitting solution for each application.

- Implement proper installation techniques and follow manufacturer guidelines to maximize system performance and longevity.

- Regularly inspect and maintain piping systems to detect and address issues promptly, minimizing downtime and costly repairs.

By carefully considering the advantages, limitations, and optimization strategies for each type of pipe and fitting solution, users can achieve cost-effective and reliable piping systems tailored to their specific needs.

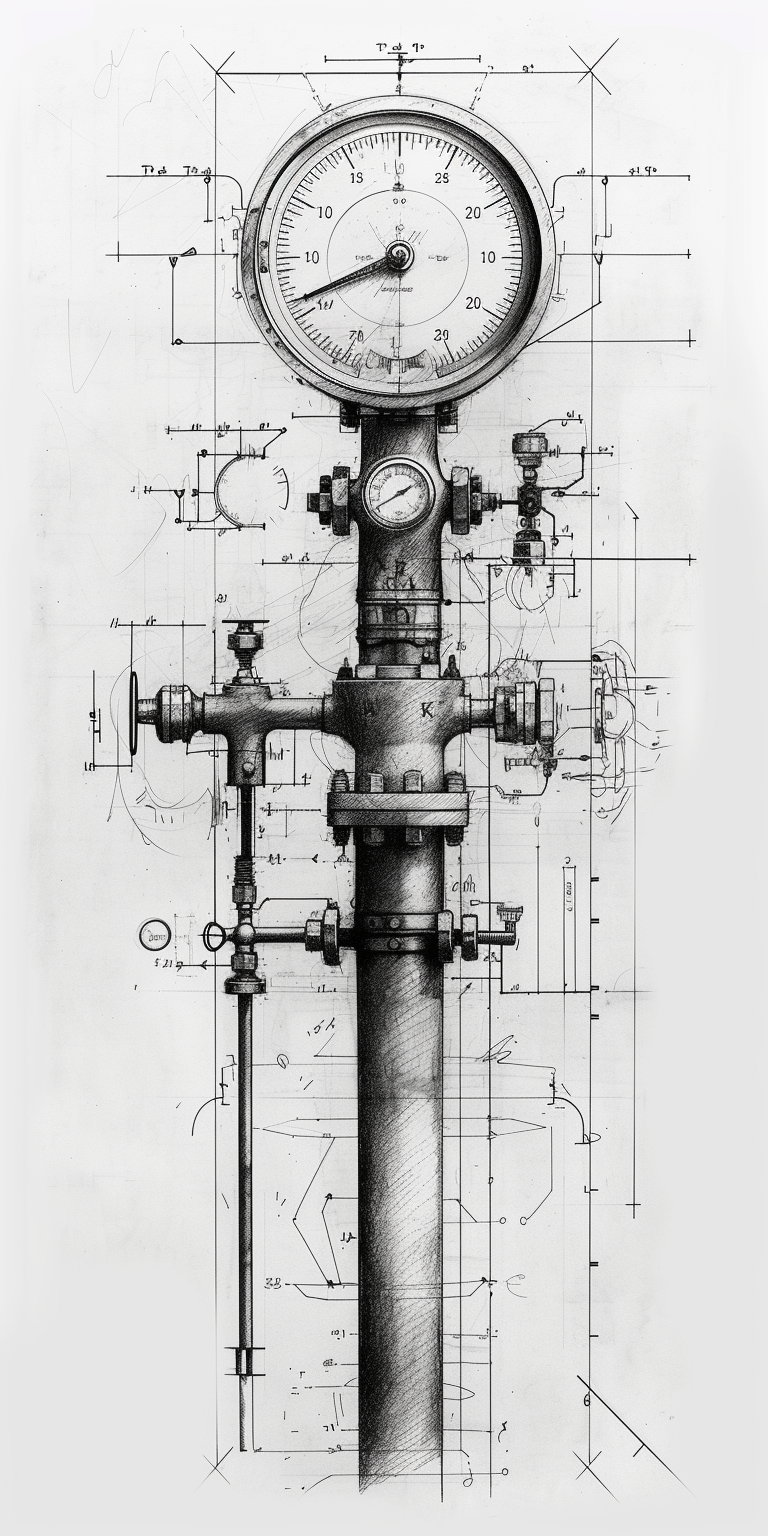

PRESSURE GAUGES, THERMOMETERS, AND TESTING ACCESSORIES

- PRESSURE GAUGE

- THERMOMETERS

- TESTING EQUIPMENT

Pressure gauges are essential instruments used across industries to measure the pressure of fluids and liquids. Found in manufacturing, oil and gas, chemical processing, pharmaceuticals, and HVAC systems, these devices ensure the smooth operation and safety of processes.

In manufacturing, pressure gauges monitor hydraulic and pneumatic systems, safeguarding machinery from damage and preventing production downtime. Similarly, in the oil and gas sector, they oversee drilling, pipeline integrity, and refining processes, aiding in flow management and environmental compliance.

Chemical processing relies on pressure gauges to maintain optimal conditions for reactions, ensuring product quality and safety. In pharmaceuticals, they regulate sterilization and purification processes, vital for producing safe medications.

HVAC systems utilize pressure gauges to monitor refrigerants, airflow, and ductwork, optimizing climate control and indoor air quality for comfort and health.

Overall, pressure gauges provide crucial data for process control, equipment safety, and quality assurance. Their accuracy enhances efficiency and reliability, making them indispensable across various industrial applications.

Thermometers are invaluable instruments employed across industries to measure the temperature of fluids and liquids, offering critical insights into process control and safety. In numerous sectors such as manufacturing, pharmaceuticals, food and beverage, HVAC, and scientific research, thermometers play a pivotal role in ensuring optimal operating conditions.

In manufacturing, thermometers are utilized to monitor temperatures in various processes, including heat treatment, chemical reactions, and material curing. Accurate temperature measurement is essential for maintaining product quality, controlling production rates, and ensuring equipment longevity.

In pharmaceutical manufacturing, thermometers are crucial for monitoring temperature-sensitive reactions, ensuring compliance with regulatory standards, and producing pharmaceutical products of consistent quality.

The food and beverage industry relies on thermometers for precise temperature control during cooking, fermentation, pasteurization, and storage processes. Maintaining proper temperatures is essential for food safety, flavor development, and shelf-life preservation.

In HVAC systems, thermometers are used to monitor air and refrigerant temperatures, optimizing heating, ventilation, and air conditioning performance for occupant comfort and energy efficiency.

In scientific laboratories, thermometers are employed for various research applications, ranging from chemical analysis to environmental monitoring and materials testing.

Overall, thermometers are indispensable tools in industries where temperature control is critical, providing essential data for process optimization, quality assurance, and regulatory compliance.

Testing equipment for measuring the pressure of fluids and liquids is essential across a spectrum of industries, ensuring operational efficiency, safety, and compliance with regulatory standards. These instruments encompass a diverse range of devices, including pressure transducers, dead weight testers, manometers, and pressure calibration equipment.

In manufacturing, testing equipment is employed to calibrate and verify the accuracy of pressure gauges and sensors used in hydraulic and pneumatic systems. Regular testing ensures reliable operation, preventing equipment malfunctions and production disruptions.

In the oil and gas sector, pressure testing equipment is utilized to assess the integrity of pipelines, wellheads, and pressure vessels. This ensures compliance with safety regulations, detects leaks, and prevents environmental hazards.

In the pharmaceutical industry, testing equipment is crucial for validating the performance of sterilization equipment, ensuring that proper pressure conditions are maintained for effective sterilization of equipment and products.

In HVAC systems, pressure testing equipment is used to measure airflow, duct pressure, and system leakage, optimizing system performance and energy efficiency while ensuring occupant comfort.

Across industries, testing equipment plays a vital role in quality assurance, process optimization, and safety management, providing accurate and reliable measurements of fluid and liquid pressures to support efficient and compliant operations.

BUILDING AUTOMATION AND CONTROL EQUIPMENT

Building Automation and Control Solutions

The Building Management System (BMS) serves as the central hub for coordinating the operation and control of various building systems and components, including FCU Controls, Damper Actuators, Sensors, IAQ Monitor, and Variable Frequency Drive (VFD). Here's how the BMS integrates and coordinates these elements to optimize building performance:

1. **Data Collection and Monitoring**: The BMS collects real-time data from Sensors and IAQ Monitors installed throughout the building. These sensors measure various parameters such as temperature, humidity, air quality, and occupancy levels.

2. **System Analysis and Control Logic**: Using the collected data, the BMS employs sophisticated control algorithms and logic to analyze building conditions and determine optimal operating parameters for each component. It considers factors such as occupancy patterns, outdoor weather conditions, and energy consumption targets.

3. **Integration with FCU Controls and Damper Actuators**: The BMS communicates with FCU Controls and Damper Actuators to adjust HVAC system settings based on the analyzed data. It modulates fan speeds, adjusts damper positions, and controls heating or cooling output to maintain desired comfort levels while minimizing energy usage.

4. **Variable Frequency Drive Integration**: The BMS interacts with Variable Frequency Drives to adjust motor speeds of pumps, fans, and other equipment in response to changing load conditions. This ensures that energy consumption is optimized according to actual demand, reducing energy waste and operational costs.

5. **Alerts and Maintenance Management**: The BMS monitors system performance in real-time and generates alerts for any anomalies or deviations from set parameters. It can also schedule preventive maintenance tasks for components based on usage patterns and manufacturer recommendations, ensuring equipment reliability and longevity.

6. **Continuous Optimization**: Through ongoing data analysis and system adjustments, the BMS continuously optimizes building performance, striving to achieve energy efficiency, occupant comfort, and operational cost savings.

Overall, the Building Management System acts as a central intelligence platform that orchestrates the operation of FCU Controls, Damper Actuators, Sensors, IAQ Monitor, and Variable Frequency Drive to create a responsive, efficient, and comfortable building environment.

The integration of FCU Controls, Damper Actuators, Sensors, IAQ Monitor, and Variable Frequency Drive (VFD) within the Building Management System (BMS) allows for comprehensive control and monitoring of various functions and parameters to optimize building performance. Here are specific functions and parameters that can be controlled and monitored through this integration:

1. **Temperature Control**: The BMS can adjust FCU Controls and VFD settings to regulate heating and cooling output based on temperature readings from Sensors. This ensures precise temperature control throughout the building for occupant comfort.

2. **Airflow Management**: Damper Actuators are controlled by the BMS to modulate airflow rates in HVAC systems. By monitoring air velocity and pressure readings from Sensors, the BMS can optimize airflow distribution to different zones within the building as per occupancy and comfort requirements.

3. **Humidity Regulation**: Sensors measuring humidity levels provide data to the BMS, which adjusts HVAC settings via FCU Controls and VFD to maintain optimal humidity levels for occupant comfort and to prevent moisture-related issues.

4. **Indoor Air Quality (IAQ) Monitoring**: IAQ Monitors detect pollutants such as CO2, VOCs, and particulate matter. The BMS receives IAQ data and adjusts ventilation rates, filtration systems, and air purification devices as needed to maintain healthy indoor air quality levels.

5. **Energy Consumption Optimization**: By integrating with VFDs, the BMS can dynamically adjust motor speeds of pumps, fans, and other equipment to match actual load requirements, thereby optimizing energy usage and reducing operational costs.

6. **Occupancy Sensing**: Sensors detecting occupancy provide the BMS with real-time data on space utilization. The BMS can adjust HVAC settings, lighting controls, and other building systems based on occupancy patterns to maximize energy efficiency and comfort while minimizing waste.

7. **Fault Detection and Diagnostics**: The BMS monitors the performance of all integrated components and sensors, identifying any malfunctions or deviations from set parameters. Alerts are generated for maintenance personnel to address issues promptly, ensuring system reliability and uptime.

8. **Integration with Building Scheduling and Automation**: The BMS can synchronize the operation of FCU Controls, Damper Actuators, Sensors, IAQ Monitor, and VFD with building schedules and occupancy patterns. Automated control strategies help optimize energy usage during unoccupied periods and reduce standby losses.

Overall, the integration of these components within the BMS enables centralized control and monitoring of critical building functions, leading to improved comfort, energy efficiency, and operational performance.

Damper actuators play a crucial role in airflow regulation and energy efficiency when integrated with the Building Management System (BMS) and other components of HVAC systems. Here's how they contribute:

1. **Airflow Control**: Damper actuators are responsible for adjusting the position of dampers within ductwork to control the flow of air. By modulating the opening and closing of dampers, they regulate the amount of conditioned air delivered to different zones within a building. This allows for precise airflow control based on occupancy, temperature requirements, and other factors.

2. **Zone Control**: In buildings with multiple zones or areas with varying heating and cooling needs, damper actuators enable individual control over airflow to each zone. The BMS receives inputs from sensors monitoring temperature, humidity, and occupancy levels in each zone. Based on this data, the BMS instructs damper actuators to adjust airflow accordingly, optimizing comfort levels while minimizing energy consumption.

3. **Demand-Based Ventilation**: Damper actuators can be integrated with the BMS to support demand-based ventilation strategies. By monitoring occupancy levels and indoor air quality (IAQ) parameters such as CO2 levels, the BMS adjusts ventilation rates in real-time. Damper actuators respond by modulating dampers to increase or decrease airflow as needed, ensuring adequate ventilation while minimizing energy usage during periods of low occupancy or when outdoor air quality is favorable.

4. **Energy Efficiency**: Properly functioning damper actuators contribute to energy efficiency by ensuring that conditioned air is distributed only where and when needed. By preventing over-ventilation and reducing unnecessary heating or cooling of unoccupied spaces, they help optimize HVAC system performance and reduce energy consumption. Integration with the BMS allows for coordinated control strategies that further enhance energy efficiency by synchronizing damper operation with other building systems based on occupancy schedules and setpoints.

5. **Fault Detection and Diagnostics**: Damper actuators integrated with the BMS can provide valuable data for fault detection and diagnostics. The BMS monitors the performance of damper actuators and dampers, detecting any malfunctions or deviations from setpoints. Alerts are generated for maintenance personnel to address issues promptly, ensuring optimal airflow regulation and system efficiency.

Overall, damper actuators contribute to airflow regulation and energy efficiency by enabling precise control over ventilation rates, optimizing comfort conditions, and minimizing energy waste in HVAC systems when integrated with the BMS and other building components.

Sensors and Indoor Air Quality (IAQ) Monitors play a vital role in ensuring indoor air quality (IAQ) and comfort levels within buildings by continuously monitoring key parameters such as temperature, humidity, CO2 levels, volatile organic compounds (VOCs), and particulate matter (PM). Here's how they contribute and how their data are integrated into the Building Management System (BMS) for real-time monitoring and control:

1. **Monitoring IAQ Parameters**: Sensors and IAQ Monitors measure various IAQ parameters to assess the quality of indoor air. These parameters include temperature, humidity, CO2 levels (indicative of occupancy and ventilation adequacy), VOCs (emitted by building materials, furnishings, and cleaning products), and PM (airborne particles such as dust, pollen, and allergens). Continuous monitoring allows for early detection of IAQ issues and enables proactive measures to maintain healthy indoor environments.

2. **Comfort Control**: Sensors monitor environmental conditions such as temperature and humidity to ensure occupant comfort. By maintaining optimal comfort conditions within predefined setpoints, the BMS can adjust HVAC system operation to prevent overcooling or overheating, reducing energy waste while enhancing occupant satisfaction and productivity.

3. **Ventilation Control**: CO2 sensors are particularly important for assessing ventilation effectiveness and indoor air quality. High CO2 levels indicate inadequate ventilation, which can lead to stuffiness, discomfort, and impaired cognitive function. IAQ Monitors continuously measure CO2 levels and provide data to the BMS, which adjusts ventilation rates as needed to ensure adequate fresh air intake and maintain IAQ within acceptable limits.

4. **Integration with the BMS**: Sensor and IAQ Monitor data are integrated into the BMS through wired or wireless communication protocols such as Modbus, BACnet, or Ethernet/IP. The BMS collects real-time data from sensors located throughout the building and aggregates it into a centralized database for analysis and control. Advanced BMS software uses this data to implement control strategies that optimize IAQ, comfort, and energy efficiency.

5. **Real-time Monitoring and Control**: The BMS continuously monitors IAQ parameters and comfort conditions in real-time. When deviations from predefined setpoints occur, the BMS triggers appropriate control actions to adjust HVAC system operation, such as increasing ventilation rates, adjusting temperature setpoints, or activating air purification systems. These interventions help maintain optimal IAQ and comfort levels while minimizing energy consumption.

Overall, Sensors and IAQ Monitors play a critical role in ensuring healthy indoor environments and occupant comfort. By integrating their data into the BMS, building operators can implement proactive control strategies that optimize IAQ, comfort, and energy efficiency in real-time.

Variable Frequency Drives (VFDs) enhance energy savings and equipment longevity by adjusting motor speed based on demand, thereby optimizing energy consumption and reducing wear and tear on mechanical components. Here's how VFDs achieve these benefits and how they are integrated and controlled within the Building Management System (BMS) alongside other components:

1. **Energy Savings**: VFDs allow for precise control of motor speed by adjusting the frequency of electrical power supplied to the motor. Instead of operating at constant full speed, VFDs modulate motor speed to match the actual load requirements of the system. This reduces energy consumption during periods of low demand, such as when building occupancy is reduced or when less airflow or fluid flow is needed. By eliminating the energy wasted in throttling control methods, VFDs can achieve significant energy savings, particularly in HVAC systems and other applications with variable loads.

2. **Equipment Longevity**: Operating motors at lower speeds using VFDs reduces mechanical stress and wear on motor components such as bearings, shafts, and windings. By avoiding abrupt starts and stops associated with fixed-speed operation, VFDs minimize mechanical shock and fatigue, extending the lifespan of motors and associated equipment. This results in reduced maintenance requirements and lower lifecycle costs for the equipment.

3. **Integration with the BMS**: VFDs can be integrated into the BMS through communication protocols such as Modbus, BACnet, or Ethernet/IP. The BMS collects real-time data from VFDs installed throughout the building and uses it to implement control strategies that optimize energy usage and equipment performance. Integration allows the BMS to adjust motor speeds based on system demand, occupancy schedules, temperature setpoints, and other factors monitored by sensors and controllers within the building.

4. **Coordinated Control Strategies**: Within the BMS, VFDs are coordinated with other building systems and components such as HVAC systems, lighting controls, occupancy sensors, and temperature sensors. The BMS analyzes data from these components to determine optimal motor speeds for energy efficiency and occupant comfort. For example, VFDs may adjust fan speeds in HVAC systems based on real-time temperature readings and occupancy levels, ensuring that airflow matches demand while minimizing energy consumption.

5. **Remote Monitoring and Diagnostics**: Integration with the BMS allows for remote monitoring and diagnostics of VFDs, enabling building operators to monitor motor performance, energy usage, and fault conditions in real-time. The BMS can generate alerts for maintenance personnel in case of abnormalities or deviations from set parameters, facilitating timely intervention to address issues and prevent equipment downtime.

Overall, Variable Frequency Drives enhance energy efficiency and equipment longevity by adjusting motor speed based on demand, and their integration into the BMS allows for coordinated control strategies that optimize energy usage and equipment performance throughout the building.